Christmas Tree

Planting

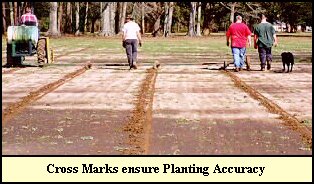

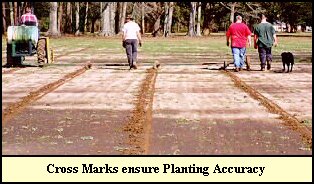

Before beginning the actual

planting process, one of the two

dimensions of the tree locations is

established. In mathematics, these

would be referred to as Cartesian,

or rectangular, coordinates. The

cross marks seen in the picture are typically parallel to the short side of the

field. Note that three marks are made simultaneously by the disks on the

boom.

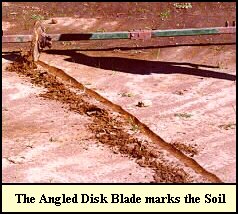

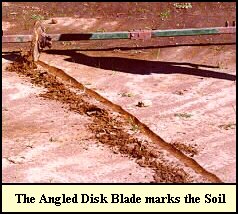

Because the marking disks are mounted at an

angle (to their direction of travel), they create

a miniature furrow as they cross the freshly

cultivated field. The planting machine will

travel perpendicular to these marks and

provide the second coordinate of the tree

locations.

Since each set of three cross marks is based on

the previous set, the potential for error accumulation is significant. To

minimize the error, marking actually begins in the middle of the field. A

string line is used to guide the first pass.

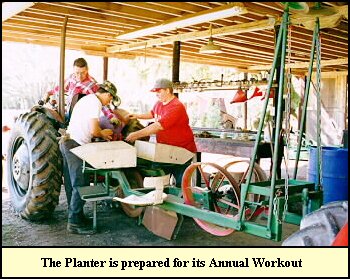

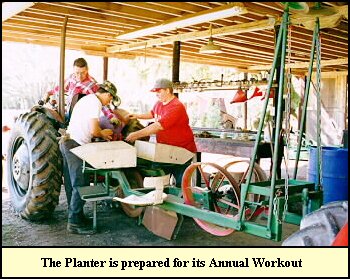

This implement was custom

designed and built for planting

trees at Shady Pond. It is a

semiautomatic device that

includes a coulter wheel (like a

giant pizza cutter), a planting

boot, packing wheels and row

markers. All of these

components can be seen in the

picture to the right. The photo

shows the machine being

hooked-up in preparation for its trip to the field. Note that the plant boxes are

stored upside down on their support structure.

The coulter slices the soil, cutting

any embedded debris. The planting

boot opens the soil so that the roots

of the little trees can be placed in

the ground. And the packing wheels

close the furrow and compact the

soil around the small plants. Finally

the row markers locate the next

succeeding row to be planted.

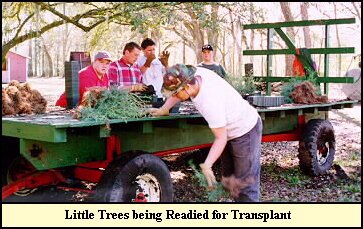

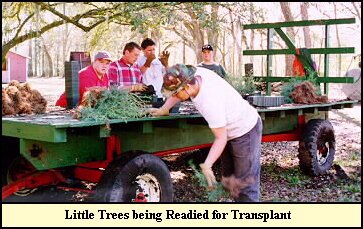

To most, preparing

containerized trees for

planting seems brutal. But at

Shady Pond the loss of even a

single tree is rare. Since the

tiny trees are usually root

bound in the pot, the root

mass is gently pounded against the wagon tires. This disturbs the roots and

signals the plant that it is no longer constrained by the pot wall...It's time to

start growing again.

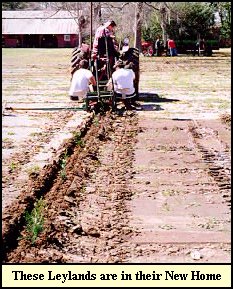

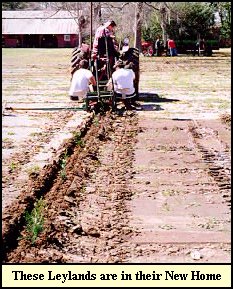

The entire operation requires a four (4) person

crew; a tractor driver, two planters who ride

on the machine, and a checker. The checker

hand plants trees that may have been skipped,

verifies the tree location and ensures the

proper soil compaction. Tree planting at

Shady Pond is done in early February. The

trees are planted in a checker board pattern at

the rate of 500 per hour.

The trick is to get the crew to plant them with

the green part up!